Cold bent steel sheet pile is formed by cold bending machine set through rolling depression and its side interlock could be continually connected to form a steel structure of sheet pile wall though produced by a different working method the use of cold bent steel sheet pile is similar to that of hot rolled steel sheet pile while their scopes of application are different to some extent.

Us steel sheet pile design.

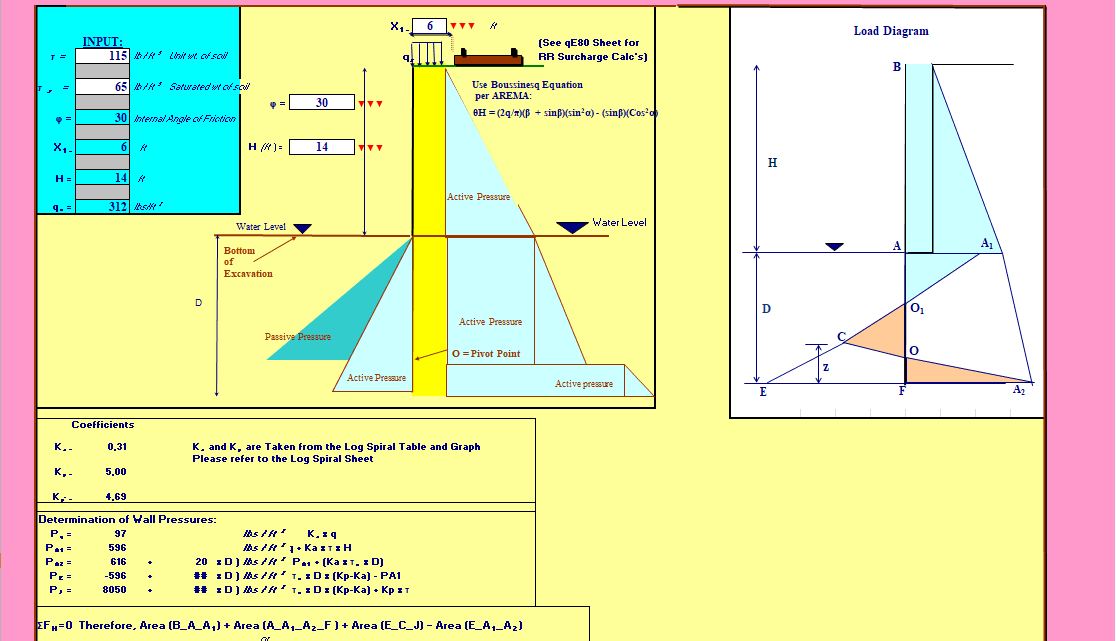

Prosheet is a comprehensive sheet pile design software for cantilever and single supported retaining walls one anchor or strut.

Computes the depth required maximum moment and section modulus required for sheet pile design based on us steel s sheet piling design manual.

Consideration is also given to the design of anchorage systems for walls and bracing systems for cofferdams.

Sheet piling 8 25 revised 06 95.

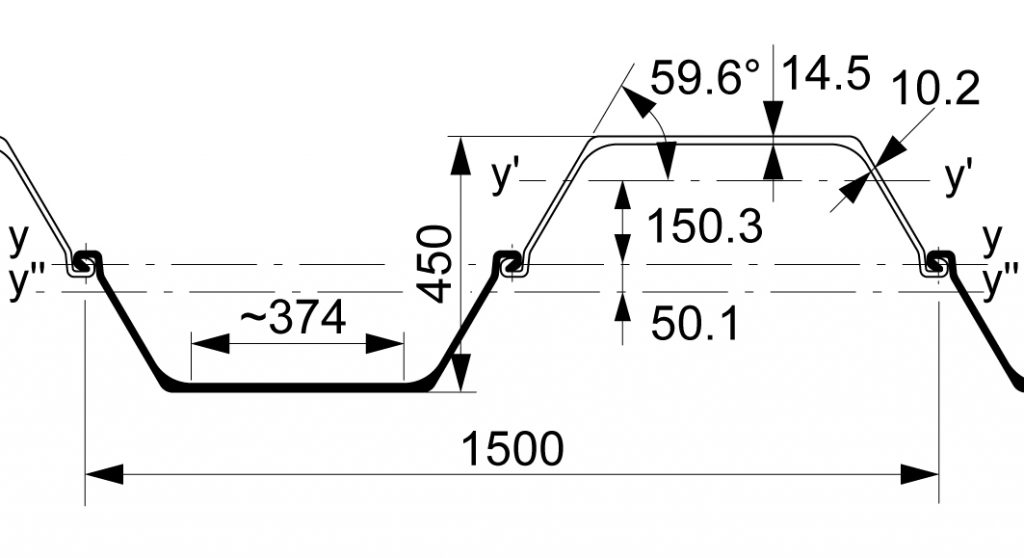

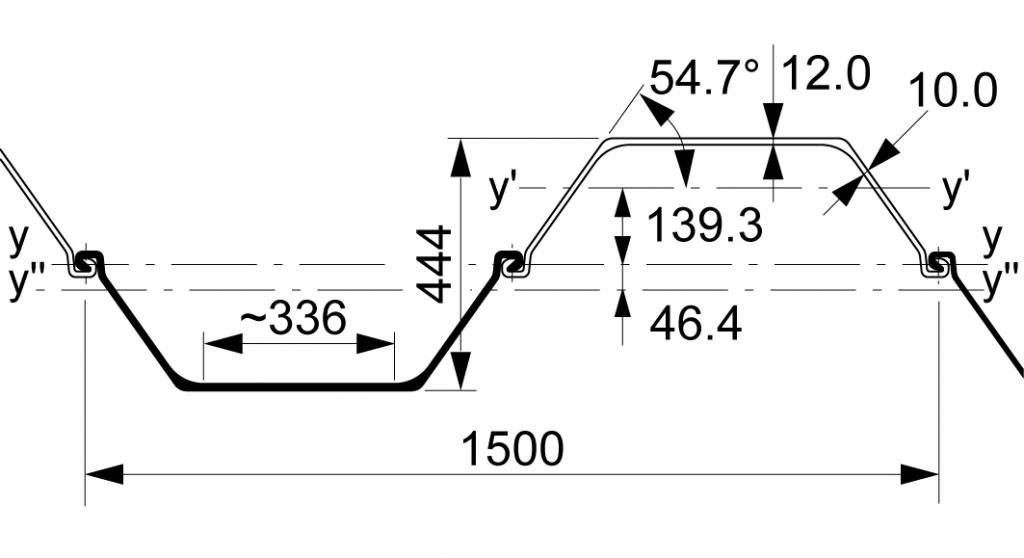

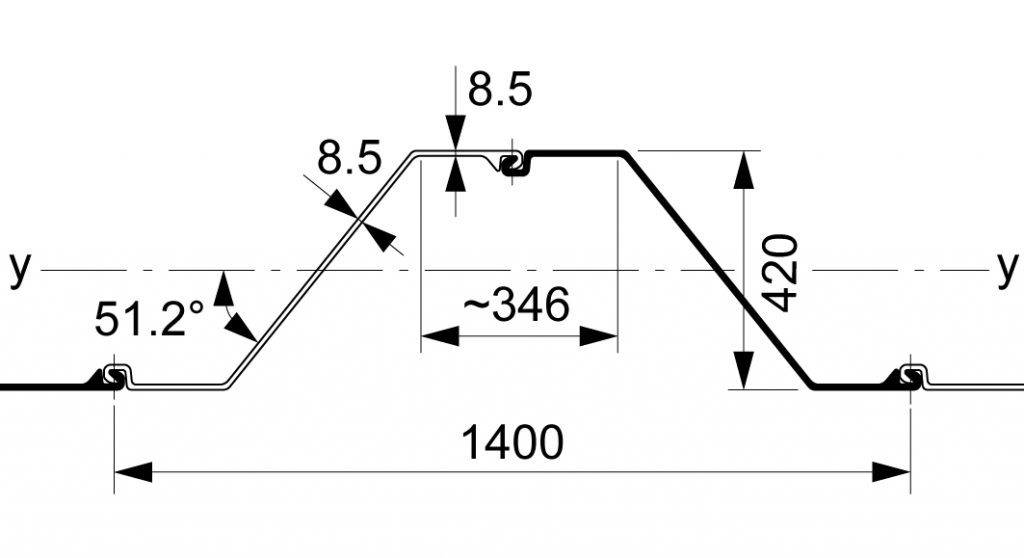

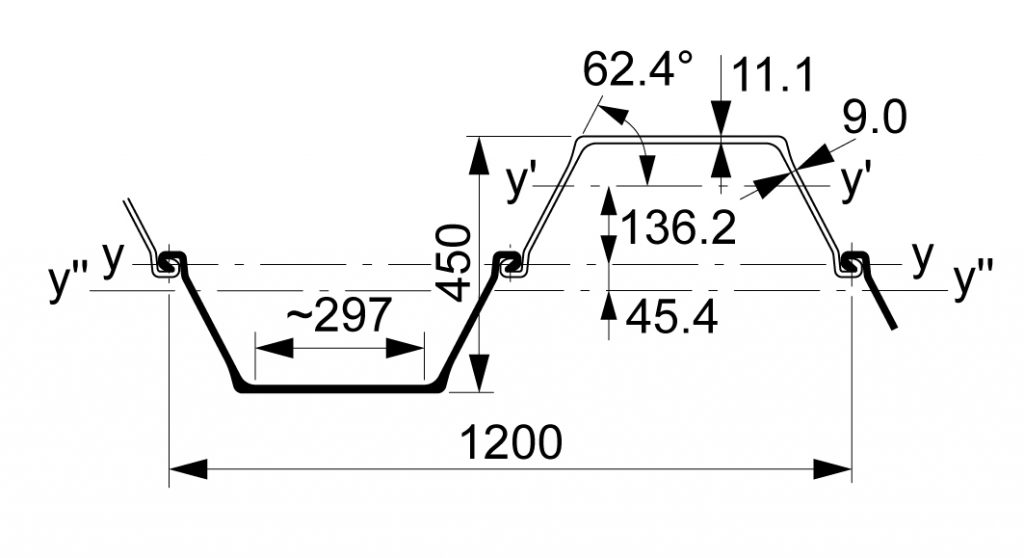

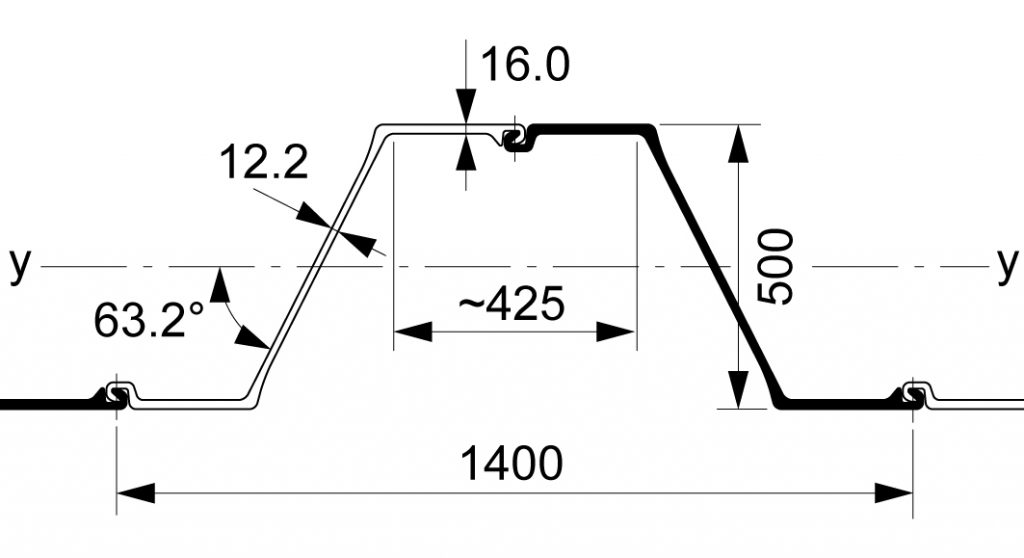

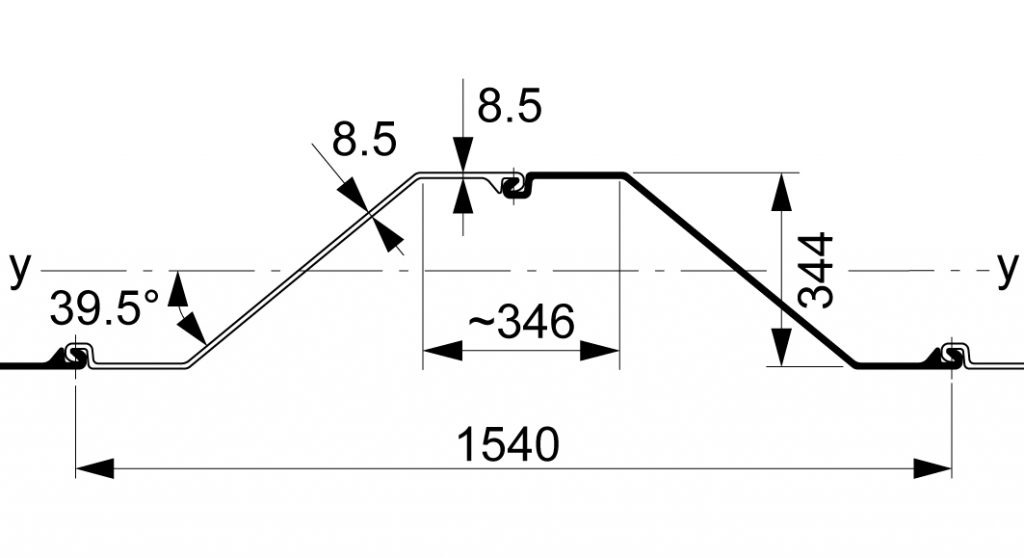

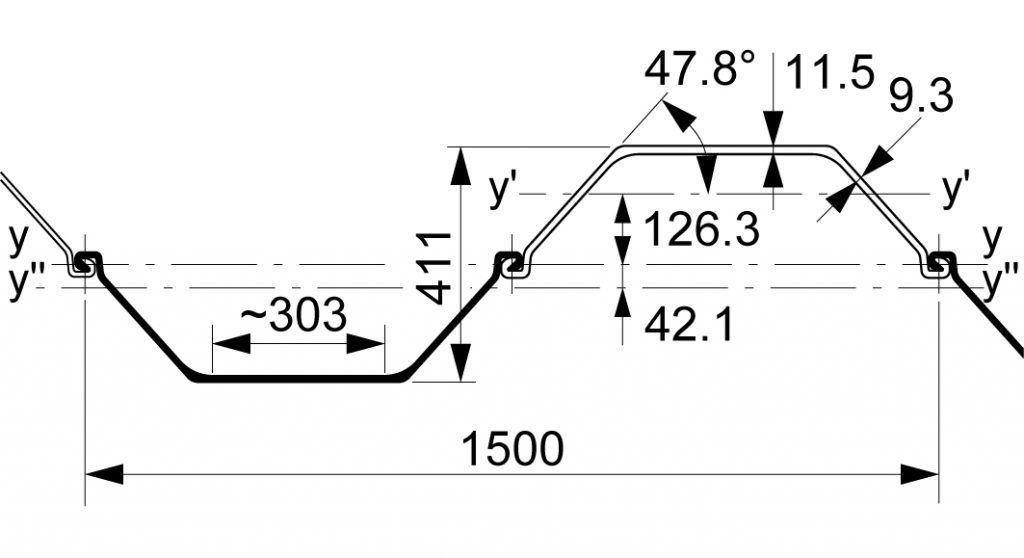

Steel sheet piles are available in a variety of standard cross sections.

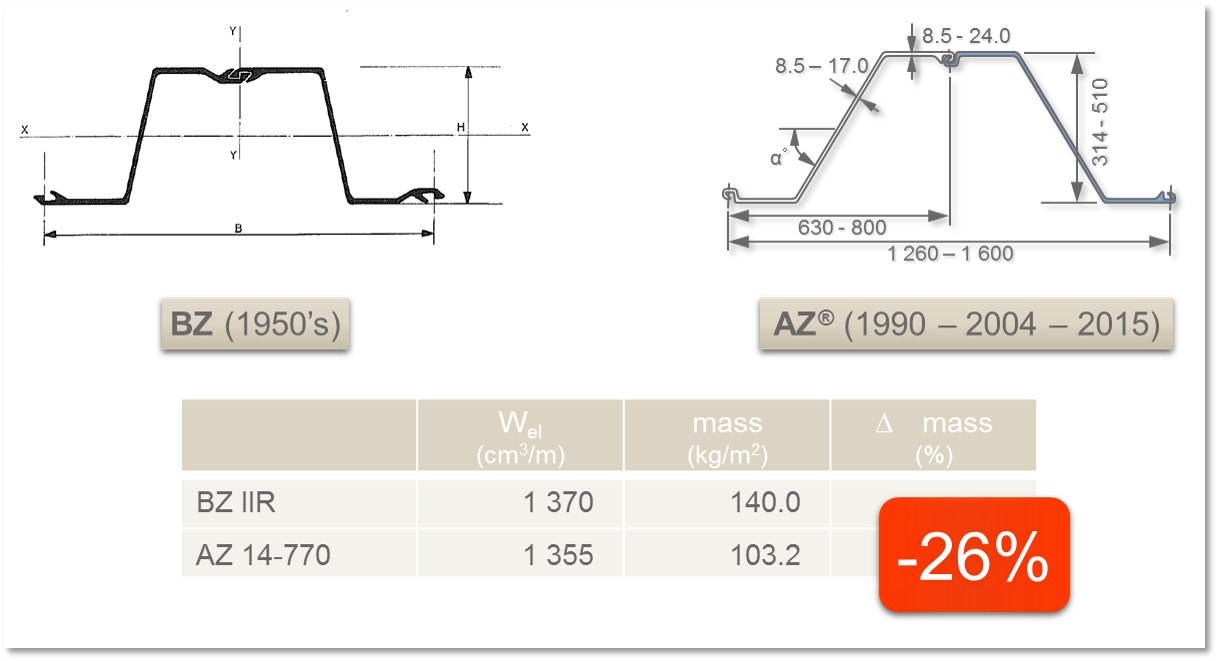

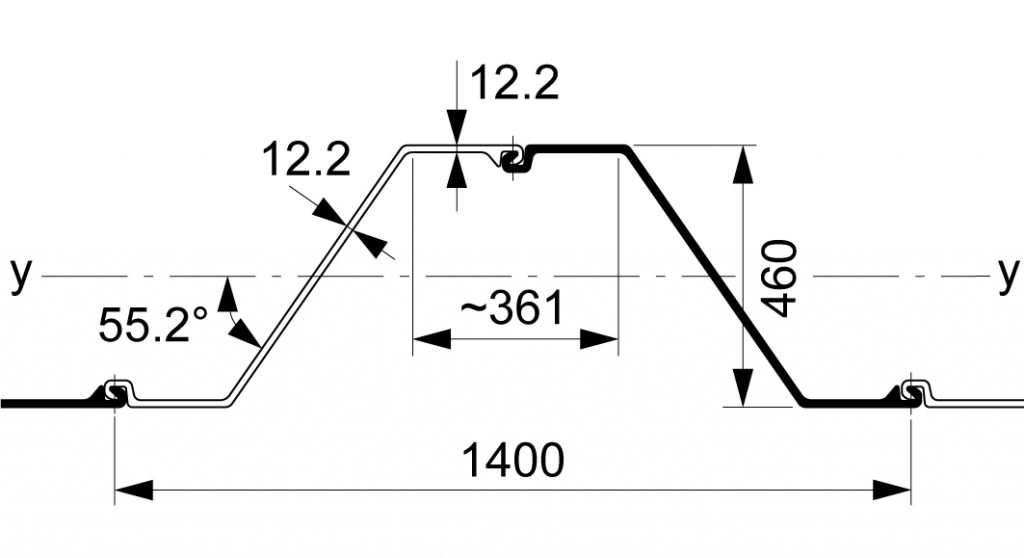

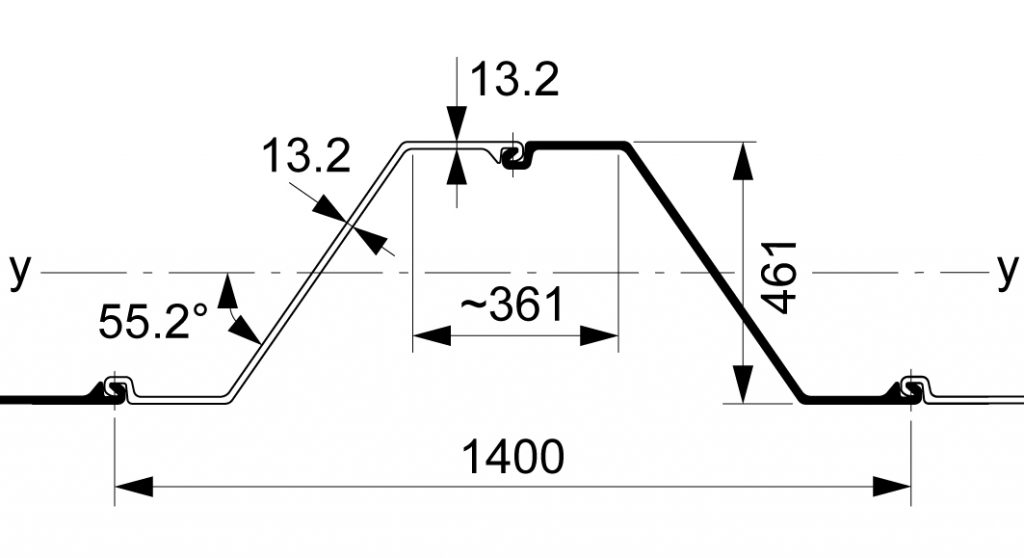

Sheet pile may be hot rolled or cold rolled piles fig.

Z type piles and amer ican society for testing and materials international astm a572 grade 50 are the most common.

There is a sheet to analyze the effects of cooper e80 loading per arema specifications.

Below s short description of the most common methods.

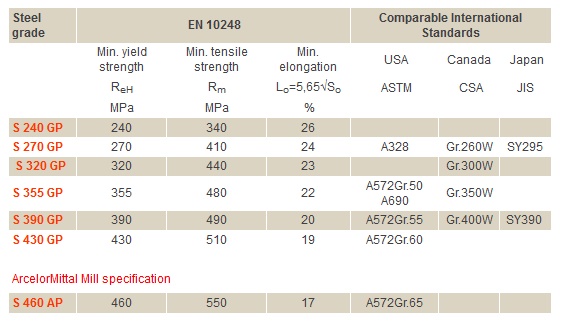

Materials steel steel sheet pile is available in various shapes types sizes weights and steel grades.

The shape or geometry of a section lends to the structural strength.

The allowable stress is thus equation 2 1.

The z type piling is predomi nantly used in retaining and floodwall applications where bending strength governs the design.

Most steel sheet piling is still designed using allowable stress design methods.

Us steel sheet pile design cantilevered wall granular soil with cooper e80 surcharge spreadsheet description.

Table 8 l 8 24 revised 06 95.

Cohesionless soil design if the sheet piling support system is to be in use for more than a month.

Sheet piling united states steel sheet piling table 8 l 8 23 revised o6 95.

For those few cases where a clay analysiswill be appropriate reference is made to the uss.

The anchor force s applied to the piling wall.

3 cantilevered and anchored retaining walls 2 braced cofferdams and 3 cellular cofferdams.

Steel sheet pile applications are typically designed to create a rigid barrier for earth and water while resisting the lateral pressures of those bending forces.

σallow freduction σy.

Thus a factor of safety is usually specified that reduces the allowable stress in the pile from the yield stress.

It is known in some countries as the allowable stress design asd for the sheet piles.

In the past the global safety factor was the rule.

There are several methods to design a sheet pile wall.

One factor applied to the steel sheet piles and one applied to the geotechnical design usually applied to the passive resistance of the soil.