The fabric to resin ratio was carefully calculated to yield a maximum of 35 resin content and process demonstrate how to produce low porosity or entrapped air bubbles large voids and microscopic porosity within the laminate.

Using sheet glass to lay up fiberglass.

Fiberglass is a very durable material that will bond to almost any surface including plastic metal wood and styrofoam.

On a small lay up the fiberglass laminate which hangs over the edge of the mold can be trimmed off easily with a razor knife if you catch the trim stage of the period after the lay up has gelled but before it has hardened.

As noted above the fiber does not have to be glass.

The styrene in polyester and vinyl ester resins evaporate into the air during lay up.

For laying up fiberglass on hard.

Too cold and fiberglass won t harden.

It is imperative to work in a well ventilated area.

Lay one of the sheets of fiberglass on the surface.

Fiberglass in temperatures between 60 and 85 degrees f.

For one square foot use about 1 cup of prepared fiberglass resin.

The mat or cloth will seem to melt into the resin as you spread it and you can use the brush and additional coats of resin to build up the layer of fiberglass to a thickness of up to 1 4 inch 0 6 cm.

Lay mat on or in your form and spread the resin mixture over it with a disposable paint brush.

If you must use several pieces line them up next to each other with as little gap between them as possible.

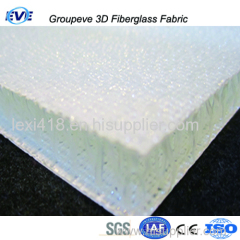

Fiberglass consists of fiberglass mat that is saturated with a fiberglass resin.

Work in a well ventilated area.

Instead heat up the room to accelerate the process.

Fiberglass resin impregnating technique.

Fiberglass is the actual cloth or mat made up of glass fibers.

Too warm and it will harden too quickly.

Protect your skin and eyes by wearing gloves eye protection and clothes to cover the skin.

The following video demonstrates the basic lay up technique to fabricate a fiberglass laminate.

Working with fiberglass and resin can be hazardous if you are not careful.

Glass cloth aka bi axial woven fabric aka bi axial.

The list below contains common designations for this material.

However this section will cover glass fiber specifically.