These left and right trunk floor extensions part no.

Welding overlap seam auto sheet metal.

My question is when i weld in the new sheet metal should i overlap the existing metal or cut a perfect patch and seam weld the metal.

840 2570 l 840 2570 r 129 99 each from auto metal direct will replace the rotted out sections on our e body project.

The rear section of the body has an overlapped.

After welding the joints were carefully sanded and in the end everything was metal finished so that the filler piece is blended in perfectly.

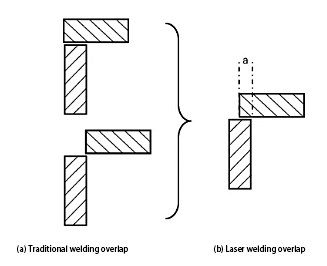

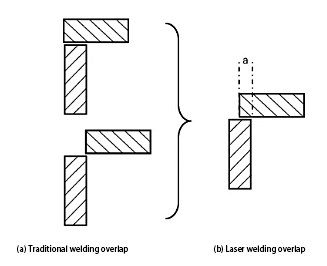

Lap joints are made by overlap ping small amounts of metal and welding the exposed edges of each section to the other on one or on both sides.

The energy efficient processes eliminate the need for added materials or contaminants such as flux agents solder solvents or crimp connectors reducing.

The holes are in the floor and not the outside body.

This of course creates a double thickness of metal at the joint overlap something that can be difficult to hide without using excessive amounts of filler.

The gap is to compensate for expansion when the metal gets hot.

You can now place a tack weld between the clecos but be very careful to make sure the panels are perfectly even.

A seam is then made by cutting down the middle of the overlap with a west cut 4 inch cutoff wheel and peeling back the remaining strip of metal.

Test fit the panel until only an even 1 16 gap is left around the patch.

This small gap will be filled in by the weld puddle.

When mig welding a patch panel onto your car you need to leave a small gap between the patch panel and the original metal.