That makes the roof stronger and eliminates one of the biggest aesthetic and functional drawbacks of screw down metal roofs.

Why are there exposed screws in my standing seam roof.

Also whereas standing seam comes in continuous length panels with no seam from the bottom of the panel to the top exposed fastener metal panels are often in standard lengths meaning there are horizontal overlaps from one panel up the roof to the next.

It s called exposed fastener because the head of the fastener is visible and not hidden by a seam.

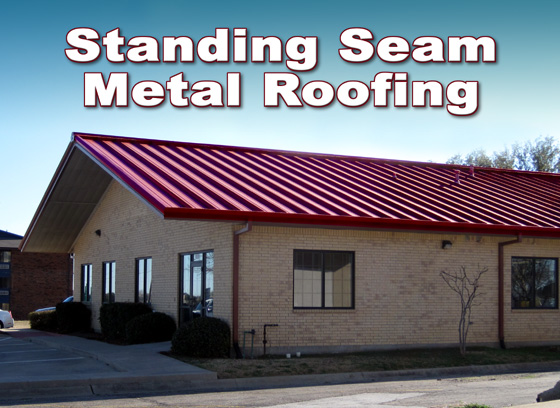

Standing seam means no exposed fasteners.

Exposed fastener metal roofs have a simple overlap from one panel to the next.

Many details in a standing seam metal roof have folds or hemmed edges that conceal the cut edge of the metal.

However instead of caulk the exposed screws where it derives its name has a rubber grommet or washer that ensures an airtight seal.

Also true standing seam is manufactured in custom continuous length panels to avoid horizontal seams along the roof.

Metal roof systems typically include a combination of exposed and concealed fasteners.

But that s really only the beginning.

Under or over tensioned screws and stripped screws aggravate the obvious which is that holes in the roof can leak if not properly executed.

These fasteners can be nails or screws.

Exposed fastener systems have been very popular in the agricultural market used on barn roofs chicken coops and outbuildings.

The most obvious difference between standing seam and exposed fastener is the lack of visible fasteners.

The screws are hidden under the roof panels and not exposed to the weather.

A standing seam metal roof variant that overlaps sheets and locks them together in the same traditional manner exists.

Exposed fasteners typically have a neoprene washer that seals the fastener head to the surface of the metal roof panel.

Corrosion will happen at some point in the lifetime of the roof.

A contractor can minimize the appearance of edge creep by using lap flashing hemming exposed edges when possible or using a paint pen on visible cut edges.

Overtime fasteners have a tendency to back out of their seated position.

Exposed fastener panels are often in standard lengths resulting in horizontal overlaps as panels are stacked vertically up the roof.

An exposed fastener system is typically considered the economical choice of metal roofing and is classically used on residential structural industrial and agricultural buildings.